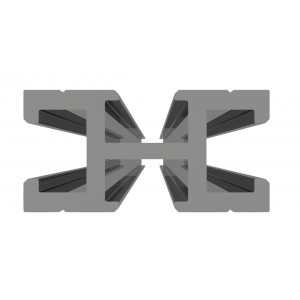

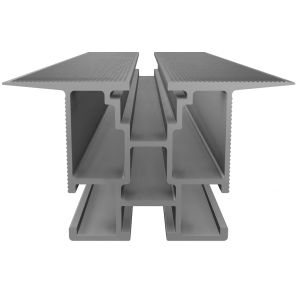

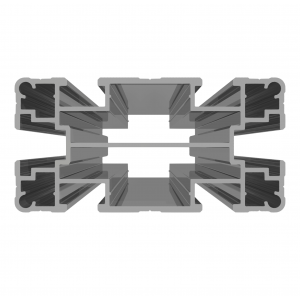

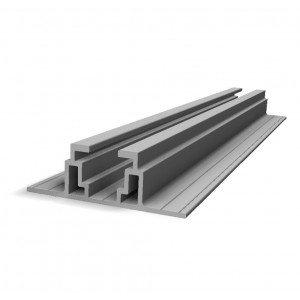

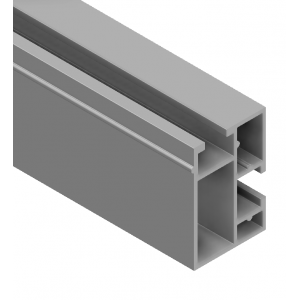

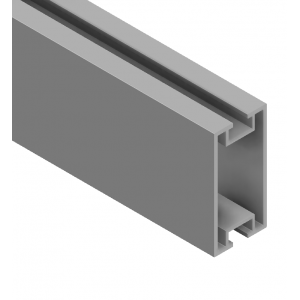

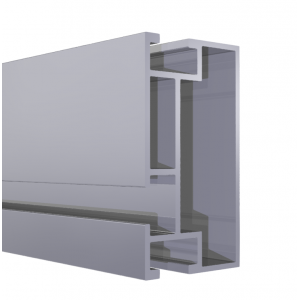

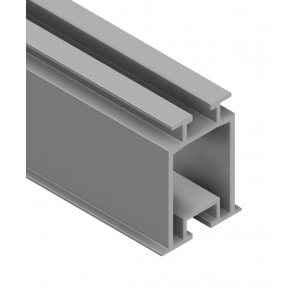

Aluminum profile SPL-2 for solar panels

0.00 грн.

Purchase Structural Aluminum Profiles at Attractive Prices from Spline Systems

Aluminum Structural Profiles Widely Used in Various Structures

Aluminum structural profiles are widely used in various structures, including guard beams, load-bearing elements, frames, and frameworks, and are important in modern machine building.

Aluminum structural profiles have found extensive application in the manufacturing of machines and production lines, as well as in frame structures.

Modern trends in the use of aluminum profiles include their application for creating 3D printers and compact machines for home use.

Their main advantages are high corrosion resistance, strength, affordable price, and versatility in engineering applications.

Aluminum engineering profiles are manufactured by extrusion.

Manufacturing Aluminum Profiles

The manufacturing of aluminum profiles is a complex and multi-stage process that includes the following steps:

- Raw Material Preparation;

- Extrusion (Pressing): The heated raw material is placed in a press, where a powerful piston extrudes the aluminum through a die. The die has a specially shaped opening that determines the final profile of the aluminum product. During extrusion, the aluminum takes the shape of the die.

- Cooling: Immediately after formation, the aluminum profile is cooled.

- Aging and Heat Treatment: After cooling, the profiles undergo an aging process that ensures their hardness and strength.

- Surface Treatment: Profiles may undergo additional surface treatments, such as anodizing (creating a protective layer) or painting to enhance aesthetic appearance.

- Cutting and Final Processing: At the final stage, the profiles are cut to specified sizes.

The final product is aluminum profiles, ready for use in various structural and engineering applications.

Advantages of Using Structural Profiles

Aluminum profiles have several advantages that make them a popular choice in many industrial sectors, including machine building, construction, and design. Here are some key benefits:

- Lightweight: Aluminum is a light metal, which simplifies transportation and installation while maintaining necessary strength.

- Strength and Durability: Despite its lightness, aluminum exhibits excellent strength characteristics, capable of withstanding significant loads. Moreover, aluminum is resistant to corrosion, which ensures a long service life for the profiles.

- Ease of Processing and Installation: Aluminum profile can be easily cut, drilled, and joined, making them convenient for quick and efficient installation.

- Aesthetic Appearance: Aluminum structural profiles have an attractive, modern aesthetic and can be anodized or coated to achieve various colors and finishes.

- Environmental Sustainability: Aluminum is fully recyclable, providing environmental sustainability for the products.

These advantages make aluminum profiles a universal choice for many industrial and commercial applications, from machine building to architectural projects.

Our range of structural profiles is the ideal solution for manufacturing machining stations, lines, and stands. SPL structural profiles are also suitable for installing solar panels.

Affordable pricing for machine profiles is available on our website.

Our range includes:

- Structural profile 20×20;

- Structural profile 40×40;

- Structural profile 40×80,

among other structural profiles.